Focus on Excellence

industry

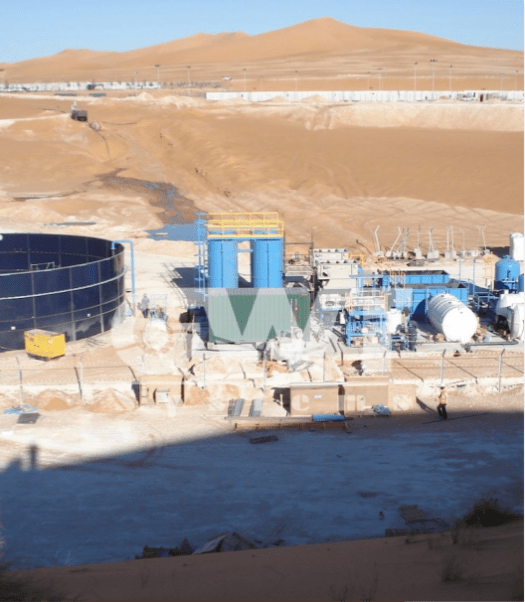

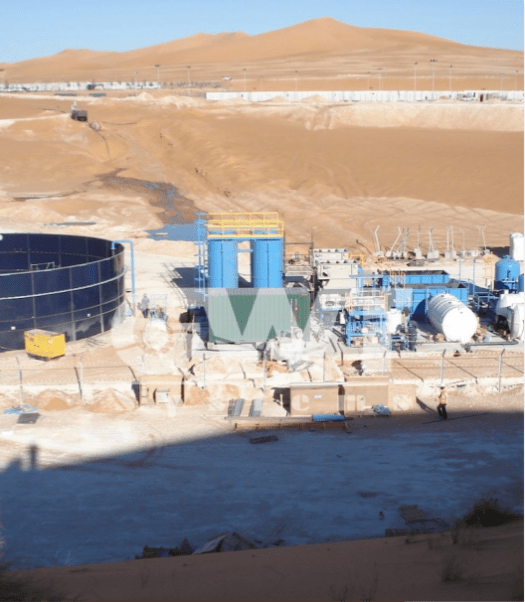

O&G Onshore / Offshore

Water produced from oil and gas extraction processes has historically been considered a waste product, but it can be turned into usable water, through several treatment processes.

Primarily, solid and oil particles are bonded together through the usage of coagulant injection. Agglomerated solids and oil particles are then separated from water through oil & water separation equipment. Fine particles can be removed through a multimedia filter or ultrafiltration technology. Dissolved hydrocarbons can be then extracted through an adsorbent filter for recovery. When the water is free of particles and oil, desalination technologies can be applied, such as, softener, nanofiltration, reverse osmosis, and ion exchange, where dissolved ions and other contaminants are separated from the water.

Food and Beverage

- Food and Beverage Ingredient Mixing

- Drinking Water

- Beverage and Ice Filtration

- Boiler and Hot Water Treatment

- Process Water Purification

- Production Utility Water

- Clean-in-Place (CIP) and Sanitize-in-Place (SIP) Processes

- Wastewater Reduction

- Dishwashers, Steamers, and Steam Tables

Petrochemicals

Commercial and Municipal

- Coagulation and flocculation. By adding positively charged chemicals to water, treatment systems can neutralize the negative charge of dirt particles and other contaminants suspended in the water. These positive chemicals and negative particles bind together into floc or larger particles.

- Sedimentation. The floc is heavier, so this treatment step utilizes the force of gravity to settle those particles to the bottom of the water. This separates a portion of the water’s contaminants, or sludge, from the water as an initial clarification step.

- Filtration. Clear water can now flow through above the settled particles from the sedimentation process. This water passes through filters of different sizes and materials, like sand and charcoal, to remove additional chemical or pathogenic particles.

- Disinfection and sterilization. Treatment systems often add disinfectants like chlorine and chloramine to the water to kill any remaining pathogens as the water travels to its final destination. Another common disinfection option is UV radiation, which utilizes wavelengths of UV light to effectively remove microbes by disrupting the structure of their DNA.

Real-world Applications

- Bathing

- Washing clothes and dishes

- Domestic and commercial cleaning

- Watering lawns

- Fire protection

- Street cleaning

- Crop irrigation

- Manufacturing processes

- Power facilities for electricity generation

Hospitality

- Reduced scale buildup in equipment and fixtures

- Increased lifespan of equipment and lower maintenance costs

- Reduced operating costs

- 30-35% reduction in the use of detergent and chemicals*

- Increased lifespan of linens

- Laundry Laundry services benefit from water softeners because they reduce the risks of stains on clothes and textiles, as well as extend the lifespan of the machinery.

- General-Use Plumbing: Hard water can cause buildup and unappealing scaling on showerheads, faucets, and sinks that are difficult to clean.

- Boilers and Pipe Systems: Scale and buildup can compromise machinery, valves, and boiler systems. Softeners reduce related maintenance tasks and repairs.

Industrial

Power

- Pre-treatment: Pretreating the water eliminates any solids, colloidal particles, and organics, as well as minerals like iron and manganese.

- Boiler feedwater: Boiler feedwater is used to minimize the levels of impurities that can damage or impede boiler operations.

- Condensate polishing: Condensate polishing is another method of reducing suspended metals, solids, and other impurities that can cause corrosion, leading to increased downtime.

- Cooling tower blowdown treatment: The result of cooling tower blowdown is reduced corrosion and cleaner discharged water.

- Flue gas desulfurization: Desulfurization removes particles like sulfur oxide, heavy metals, and gypsum from power generation water emissions.

- Recycling and reuse: Recycling and reusing emissions ensure a consistent flow of clean water while reducing discharge and raw water intake.

Utilities and Infrastructure

Marine

Steel

One Stop

For Everything Water

GWT has been repeatedly recognized for providing innovative quality solutions in all sorts of water and waste water treatment requirements. GWT has provided solutions to a wide range of