Focus on Excellence

industry

Power

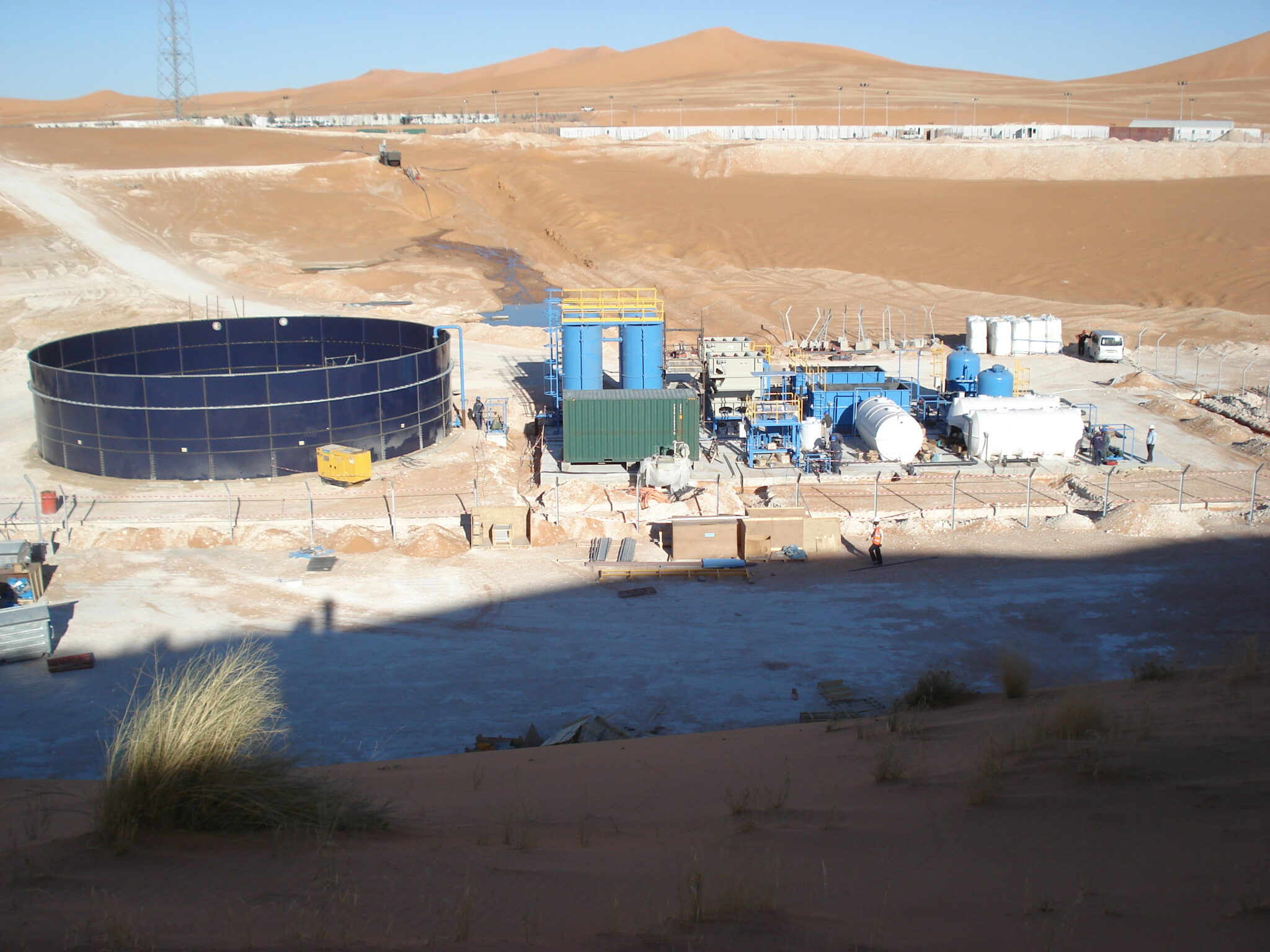

Treated water is essential for reducing wear and tear on processing equipment. Mineral, microbial, and chemical contaminants can prematurely corrode and degrade expensive equipment for energy generation, storage, and distribution. Treating and purifying water allows you to reuse it without risking damage to your systems, dispose of it while complying with wastewater regulations, and minimize your facility’s environmental footprint.

Generating power takes vast amounts of water for use in virtually every step of the process, from boiler feed systems to cooling condensers and bearings to pollutant scrubbers. Clean water is not just important for intake but equally essential for discharge. Legislation continues to evolve, tightening restrictions and shifting demand toward zero liquid discharge. That means there’s an increase in innovation in water treatment for the power generation industry.

According to trend analysis, water demand will increase by 55% due to the world’s growing population, while demand for electricity will increase by 45 trillion kWh or approximately 44% more than the 2018 level. That presents a dilemma when power plants depend on water for clean energy generation. The answer is Gulf Water Treatments advanced technology combined with expertise to find smarter, cleaner ways to preserve and recycle water to meet power requirements for an increasingly connected, electronic world.

There are various Gulf Water Treatment approved systems available for power plant water treatment, such as:

- Pre-treatment: Pretreating the water eliminates any solids, colloidal particles, and organics, as well as minerals like iron and manganese.

- Boiler feedwater: Boiler feedwater is used to minimize the levels of impurities that can damage or impede boiler operations.

- Condensate polishing: Condensate polishing is another method of reducing suspended metals, solids, and other impurities that can cause corrosion, leading to increased downtime.

- Cooling tower blowdown treatment: The result of cooling tower blowdown is reduced corrosion and cleaner discharged water.

- Flue gas desulfurization: Desulfurization removes particles like sulfur oxide, heavy metals, and gypsum from power generation water emissions.

- Recycling and reuse: Recycling and reusing emissions ensure a consistent flow of clean water while reducing discharge and raw water intake.

One Stop

For Everything Water

GWT has been repeatedly recognized for providing innovative quality solutions in all sorts of water and waste water treatment requirements. GWT has provided solutions to a wide range of

Get In Touch

Fill all information details to consult with us.