Focus on Excellence

industry

Paper and Textile

Papermaking is a highly sophisticated process involving several processing steps to turn wood into paper products. In addition to the actual papermaking process, there are also supporting areas such as wastewater treatment, recovery boiler operation, steam production, and cooling towers that benefit from online analytical measurements.

In the Pulp and Paper industry, a lot of effort is used to water, close water circuits, and reduce substantially the environmental impact, by process modeling and Kidney technologies as internal process water treatment.

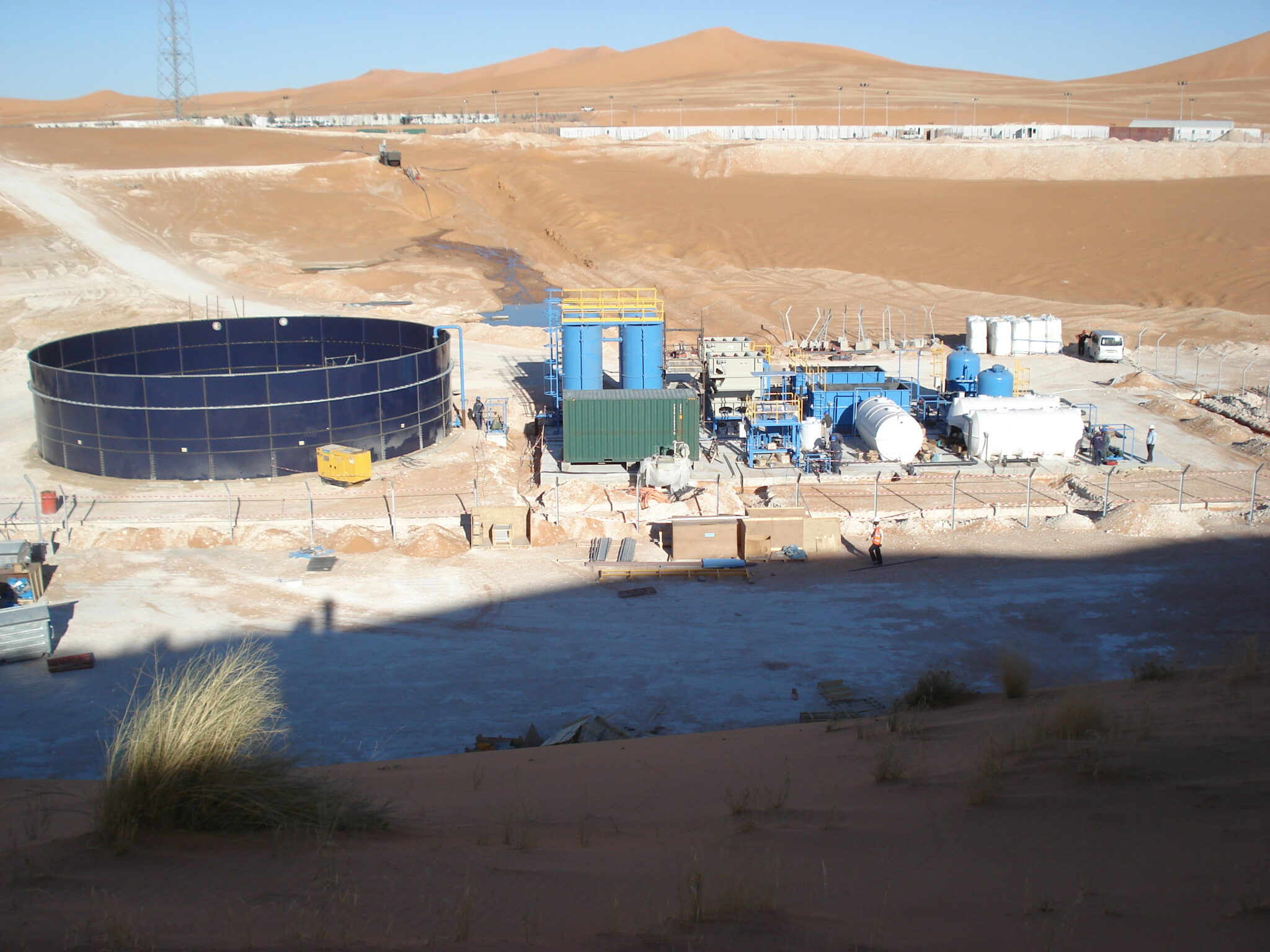

Effluents from pulp and paper mills contain solids and dissolved matter. Gulf Water Treatments methods used to remove solids from pulp and paper mills effluents are screening, settling/clarification, and flotation. The method chosen depends on the characteristics of the solid matter to be removed and the requirements placed on the purity of the treated water.

The separation of solids from the effluents is accomplished with help of screens, grid chambers, and settling tanks. Screens are units that operate according to the sieving/filtration process. The function of the screens is to remove coarse, bulky, and fibrous components from the effluents. The grit separating systems currently in use are subdivided into longitudinal grit traps, circular grit traps, and vortex grit traps, depending on their design and process layout.

The paper industry uses a variety of Gulf Water Treatment systems and the preferred process combination for each individual case depends on the grade-specific quality of the effluent that is going to be treated.

One Stop

For Everything Water

GWT has been repeatedly recognized for providing innovative quality solutions in all sorts of water and waste water treatment requirements. GWT has provided solutions to a wide range of